Embora as especificações elétricas chamem mais atenção, a integração mecânica frequentemente determina a confiabilidade a longo prazo em aplicações industriais. Vibração, expansão térmica, tensões de montagem e proteção ambiental apresentam desafios que exigem um projeto mecânico cuidadoso.

O SFTO1400WN-7391AN fornece uma excelente base para uma integração de sistema robusta, mas entender suas características mecânicas é essencial para o sucesso.

Precisão Dimensional para Integração Perfeita

As dimensões precisas do módulo (315,81×186,07mm) com tolerâncias de ±0,3mm garantem um ajuste consistente em todas as unidades de produção. As principais considerações mecânicas incluem:

-

Perfil de 3,0mm (sem PCB) para designs finos

-

Profundidade máxima de 5,1mm com placa controladora

-

Peso de 284g para montagem resistente à vibração

Desempenho de Vibração e Choque

Ambientes industriais exigem resiliência mecânica. Os testes de confiabilidade do módulo incluem:

-

Teste de vibração: 1,5G, 10-500Hz, 1 hora por eixo

-

Resistência ao choque: 220G, onda senoidal de meio ciclo de 2ms

-

Ciclagem térmica: -20°C a 60°C, 100 ciclos

Essas especificações indicam adequação para transporte, automação industrial e aplicações em equipamentos portáteis.

Melhores Práticas de Estratégia de Montagem

A integração bem-sucedida requer atenção à mecânica de montagem:

-

Tensão Distribuída: Evite concentrar a pressão de montagem perto da área ativa

-

Expansão Térmica: Leve em consideração os diferentes CTEs entre o display e o gabinete

-

Alívio de Tensão do Conector: Fixe o conector eDP contra falhas induzidas por vibração

-

Proteção ESD: Implemente o aterramento adequado para a blindagem do gabinete

Considerações de Vedação Ambiental

Embora o display em si não seja selado, o design adequado da junta em seu gabinete pode alcançar:

-

Proteção IP54 para resistência a poeira e água

-

Prevenção de condensação em ambientes úmidos

-

Proteção contra contaminação em ambientes de fabricação

Protocolos de Manuseio e Montagem

A ficha de dados enfatiza vários requisitos críticos de manuseio:

-

Proteção ESD durante a montagem

-

Sequência de engate do conector adequada

-

Evitar a tensão na superfície do polarizador

-

Sequenciamento de energia correto para evitar danos

Métodos de Verificação de Confiabilidade

Além da conformidade com as especificações, considere estas abordagens de validação:

-

Teste de ressonância mecânica de sua montagem completa

-

Imagens térmicas sob condições de carga máxima

-

Teste de vibração de longo prazo simulando transporte do mundo real

-

Teste de ciclo de inserção/extração do conector

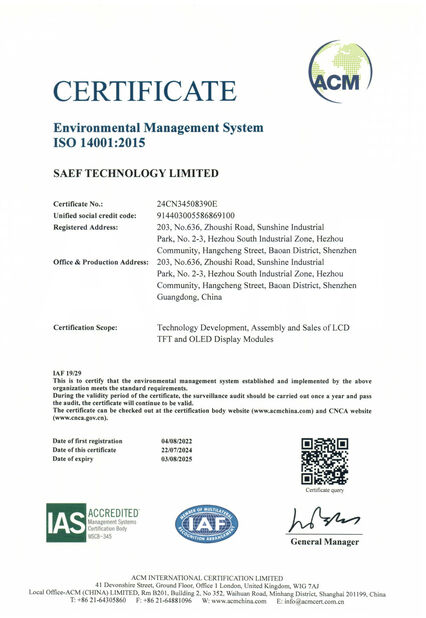

A robustez mecânica deste display reflete a compreensão da Saef Technology Limited de que os componentes industriais devem sobreviver além do laboratório. Ao fornecer dados mecânicos abrangentes e diretrizes claras de manuseio, eles permitem que os designers criem produtos que resistam às condições do mundo real.

Enfrentando uma integração mecânica desafiadora? Nossa equipe de engenharia pode fornecer orientação específica sobre técnicas de montagem, vedação e amortecimento de vibração para sua aplicação.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!